5 Common Mistakes People Make when Constructing a Steel Building

There are many factors to consider when constructing a steel building. Steel buildings have become a favourite for many, largely because of the durability and longevity of such buildings. Most garages are now made from steel and an increasing number of workshops and commercial constructions are wholly-steel except maybe for windows and ventilations. The versatility and customizability of steel are two other factors that seem to be attracting so many people.

However, one thing all steel builders agree on is that steel buildings are best constructed by experts of the trade. It’s not just about welding one metal piece to another or cutting away sections of the sheet to create openings for doors and windows.

Common Mistakes – Constructing a Steel Building

If you’re doing a DIY project or are a budding steel builder working on your first project, here are 5 common mistakes you should be wary of when constructing a steel building.

1. Not following steel building codes when constructing a steel building

The first step in building a steel structure should be to obtain a license that allows you to erect the construction at that the desired location. The fact that you’ve seen your neighbours building their steel garages around doesn’t mean that you’ll be allowed to erect a steel workshop in the area.

You’ll also be required to follow the right building codes. Building codes are a set of rules that specify the minimum allowable safety levels for constructions such as buildings. Take time to check the National Building Codes for Canada (NBC) or the America Institute of Steel Construction (AISC) codes.

2. Building the wrong building when constructing a steel building

Another mistake steel builders often make is to design and construct the wrong building. If you’re building a workshop, do you know the features of a workshop? Or are you going to come up with a large garage and call it a workshop? Some of the questions to ask before you start constructing a steel building include;

3. Failing to budget for the whole kit when constructing a steel building

Traditionally, steel building kits come without windows, doors, skylights etc. One mistake most builders will make when budgeting is to leave out the costs of these important parts. So at the end of the day, you have a budget which you think is right but which in reality is several hundred or a few thousand dollars short of the actual value. If this mistake is not uncovered and corrected earlier on in the project, you can easily end up recording double transportation expenses.

Insulation mistakes

1. Choosing the wrong insulation when constructing a steel building

This is a common and very costly mistake that many steel builders make. Steel buildings are not wood or concrete buildings so you’ll need a different type if insulation. Spray-on insulation will usually work very well because it easily sticks onto the metal while consuming negligible space. We also provide insulation that is custom designed for the interior walls of our structures!

2. Not applying enough insulation, failing to join seams, and cutting the insulation wrong when constructing a steel building

Once you have the right insulation, what follows is to install it properly. Applying insulation can be a little difficult because it involves removing the plasterboard, applying the insulation and then redecorating. Metal conducts a lot of heat so you need to apply a reasonable amount of insulation.

For rigid form and fiberglass insulations you’ll need to join the seams using tape. Although this is a simple process, many often forget it. Rigid form and fiberglass insulations must also be cut correctly to avoid future problems. Avoid any gaps which could form escape routes for heat.

Overall, if you can avoid these 5 common mistakes, you should be confident of constructing a durable, attractive, and energy efficient steel building.

Choose Future Steel Buildings When Constructing a Steel Building

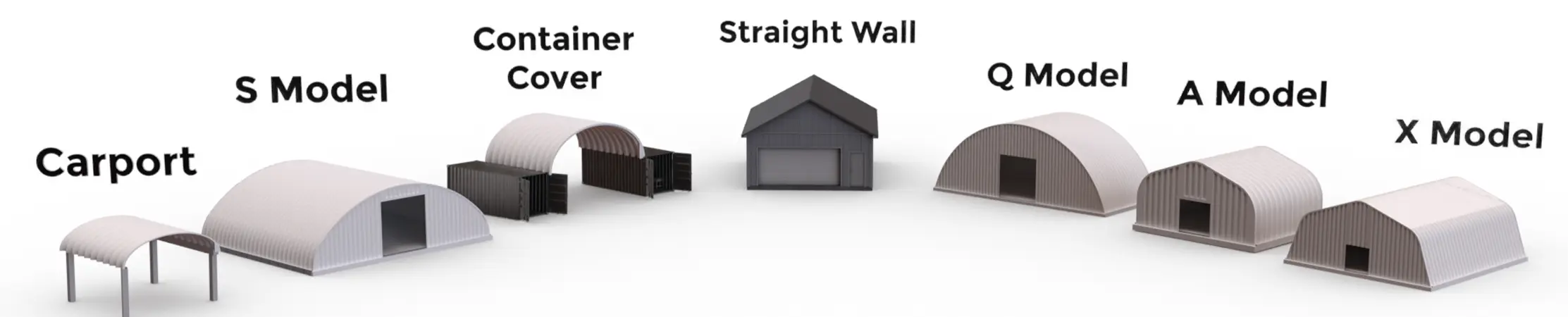

Future Steel Buildings has the Prefabricated steel building packages for you, designed to offer quick construction and customization that satisfies all your requirements. Whether you need simple storage for your boat or RV, a shelter for your livestock, a small garage, a workshop and more, these metal buildings offer the perfect solution.

Manufactured from Galvalume Plus™ Steel, these roofs are built to withstand the harshest weather conditions, including strong winds, heavy snow, and even fire. Galvalume Plus™ Steel is known for its exceptional corrosion resistance, which ensures that the roofing system remains in excellent condition for decades. In fact, Future Buildings offers a 50-year warranty against rust perforation on all their metal buildings.

The high-quality steel used in these metal arch roofing systems is sourced directly from ArcelorMittal Dofasco, ensuring consistent quality and optimal pricing. This commitment to quality materials means that customers can trust in the long-term performance and reliability of their metal arch roofing system. Read more about Galvalume Plus™ Steel at their website.

A Future Building kit offers quick construction, unparalleled longevity, and multiple customization options. You can choose from a list of steel building styles, including A, X, S, Q, T, and R styles depending on your unique needs.

If a straight walled building style is your preference, check out our sister company, Toro Steel Buildings.

To learn more about how our steel building systems can meet your needs, or for more information about any of the other metal buildings we offer, contact us today.

Call us directly at 1-800-668-5111 to speak to an expert in your region, or fill out our online form to request a quote.

Related posts